Measurement of resistance and insulation condition of MV cables in the cooperation system of the e²TANGO protection controller and the measuring disconnector in the connection compartment of the MV switchgear

We invite you to read the article on solutions for MV electric motors powered by switchgears, prepared by Mariusz Radziszewski and Dariusz Rybak from Elektrometal Energetyka SA

Due to moisture, an uncomfortable place of use or difficult and even extreme working conditions, a significant number of users struggle with the problem of controlling the resistance and insulation condition of MV cables supplying medium voltage electric motors in industrial plants, mines, power plants or combined heat and power plants. The solution of Elektrometal Energetyka, successfully used in mining facilities, introduces the possibility of automatic checking of parameters inside the MV switchgear with a simultaneous preview of the measured values on the e2TANGO protection controller screen.

Previous methods of control, such as external measuring systems, meters and other devices controlling the resistance and insulation condition before attempting to switch the motor on, performed their task to a limited extent. The choice of these methods involved periodic access to information about the situation inside the switchgear and required additional actions on the part of the user.

At the special request of our customers, a more automated solution for resistance measurement and insulation condition control was created, in the form of additional functionality of the e2TANGO protection relay. This solution includes:

Protection relay e2TANGO

Isometric adapter (high voltage generator)

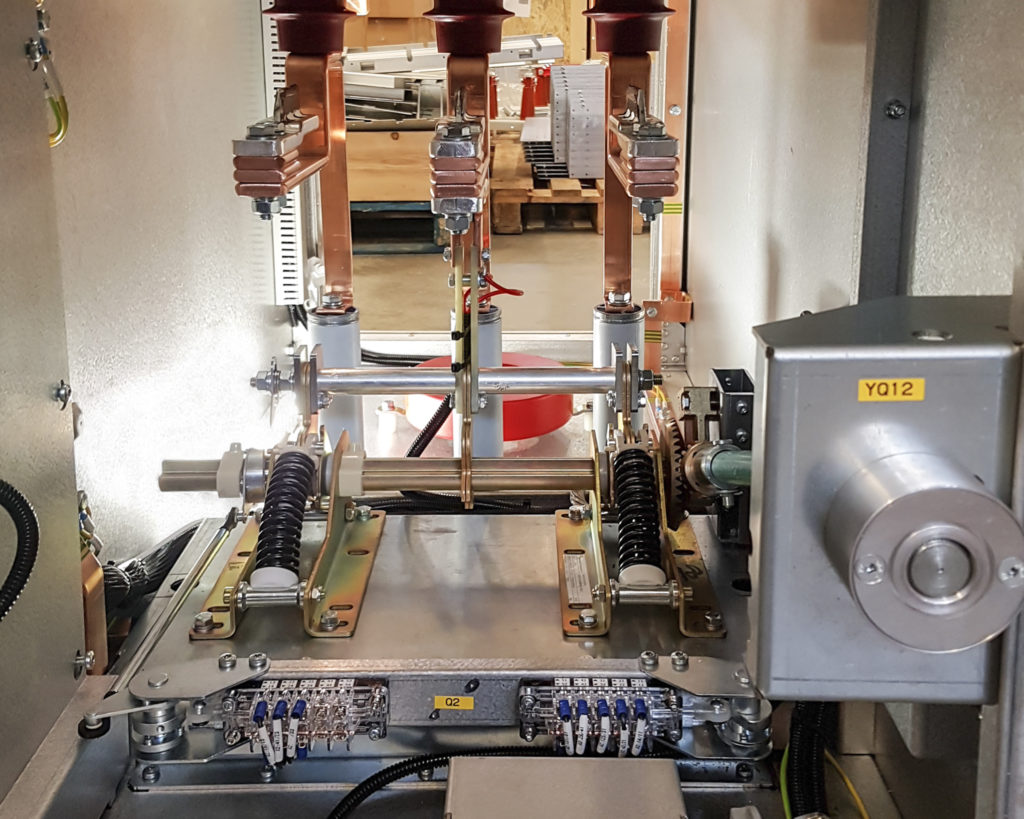

Special measuring disconnector installed in the MV switchgear terminal compartment

The individual elements of the measurement system are presented in the infographics below.

Fig.1 View of the e²TANGO protection relay with resistance measurement and insulation status control

The user of the MV switchgear gives the e2TANGO protection relay an order to start the automatic cyclic measurement of resistance and insulation condition of medium voltage cables. According to the programmed cycle, the controller uses the output card to start the DC generator connected to the tested system via a measuring disconnector located in the connection compartment.

The value of the generated high voltage and current is sent via low-level analog signals to the e2TANGO relay, which measures these signals and on their basis calculates the insulation resistance in appropriate moments and determines the absorption coefficient α. Depending on the setting, the coefficient can be determined by the PI method (based on the resistances measured after 30 seconds and 3 minutes from the moment of applying high voltage) or DAR (after 15 and 60 seconds).

After the attempt is completed, the driver waits a certain amount of time and starts the process all over again. If the resistance is within the values specified in the e2TANGO relay settings, the system enables the MV motor to be switched on. The e2TANGO relay can also be programmed to block the switching on of the circuit breaker when the insulation parameters do not fall within the set limits and send information to the user about the need to dry the motor.

Depending on preferences, measurement can be performed both automatically, using the driver, and manually. The system is equipped with the option of connecting to the connector of another device, which enables manual measurement with an external device.

Fig. 3 Test disconnector in the MV switchgear terminal compartment

Summary

The additional functionality of the e2TANGO protection relay, supporting the measurement of resistance and control of the insulation condition of MV cables, is a solution that ensures even greater convenience in the use and operation of medium voltage devices, in particular MV motors. Our engineers have prepared a solution for fully automatic control and preview of the resistance status of MV cables at any time of operation, without the need to use special measuring equipment. The measurement system has already proven itself in facilities with extremely difficult operating conditions, including KGHM, which makes it suitable for use also in other energy sectors.